Industry prospects and applications of high-temperature nanographite fillers

2024.10.24

2024.10.24

Vijesti iz industrije

Vijesti iz industrije

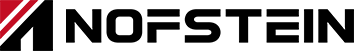

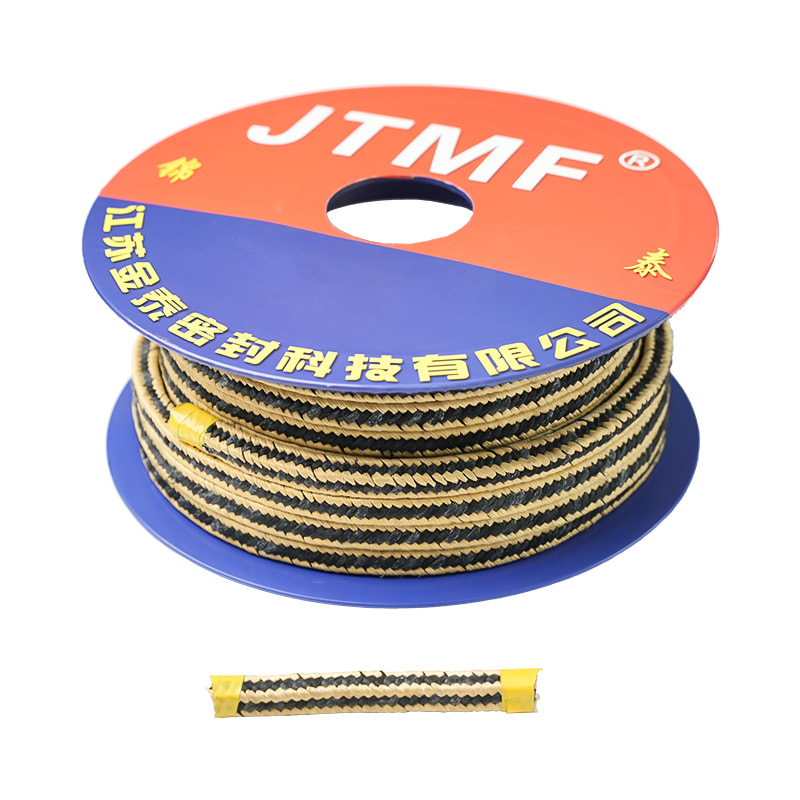

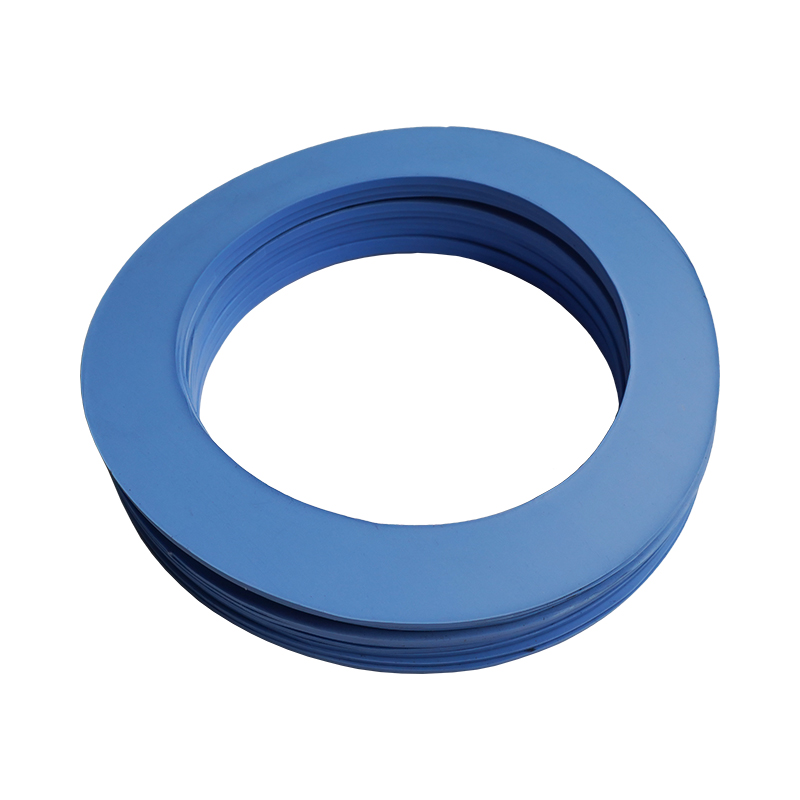

Among many sealing materials, high-temperature nanographite Gland Packing have gradually become a popular choice in the market due to their excellent high-temperature resistance, excellent chemical stability and excellent self-lubricating properties. With the continuous advancement of industrial technology, the performance requirements of various types of mechanical equipment for sealing materials are also increasing.

Product Overview

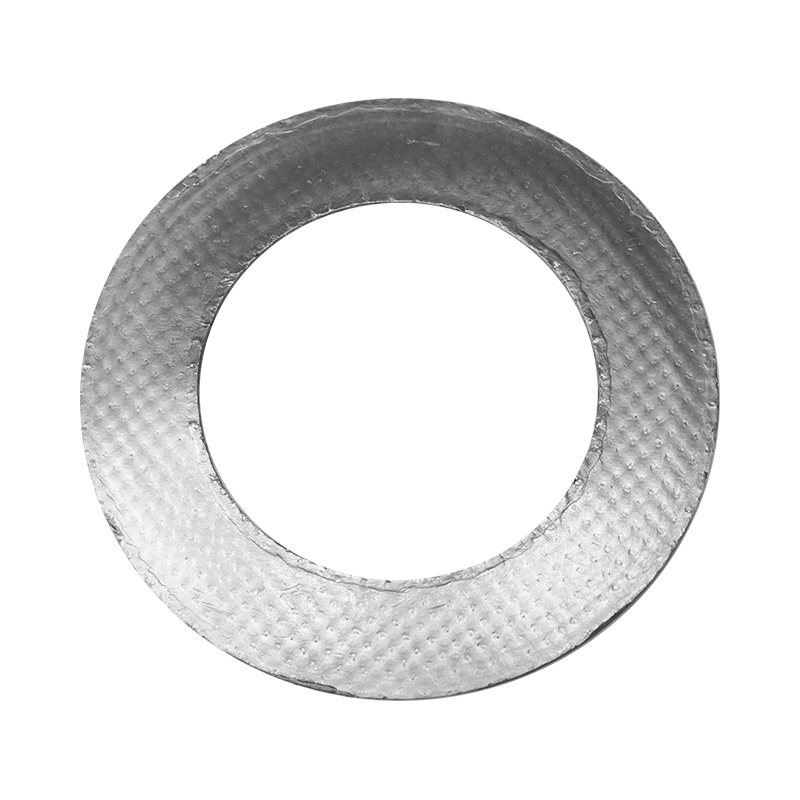

High-temperature nanographite filler is a new type of sealing material that uses nano-grade graphite as the main component and has superior physical and chemical properties than traditional graphite Gland Packing. It can maintain a good sealing effect under extreme temperature conditions (usually up to 500°C) and is widely used in high-temperature and high-pressure occasions in industries such as petrochemicals, metallurgy, electricity, and papermaking.

Performance advantages

High temperature resistance: The heat resistance of high-temperature nanographite Gland Packing far exceeds that of traditional Gland Packing. It is suitable for high-temperature and high-pressure environments, can effectively prevent oil and water leakage, and improve the safety and stability of equipment.

Excellent chemical stability: The product has good resistance to most chemical media, especially in corrosive environments such as acids, alkalis and solvents. This makes it very reliable in the application of chemical equipment and storage tanks.

Self-lubricating property: The self-lubricating property of high-temperature nanographite enables it to reduce friction, improve equipment operation efficiency and reduce maintenance costs. This property is particularly important in rotating machinery, pumps and valves and other equipment.

Environmental protection: Compared with some traditional sealing materials, the manufacturing process of high-temperature nanographite Gland Packing is more environmentally friendly, does not contain harmful substances, and meets the needs of modern industry for sustainable development.

Application areas

The application areas of high-temperature nanographite Gland Packing are very wide, including but not limited to:

Oil and gas industry: Provide efficient sealing solutions during oil drilling, refining and transportation.

Chemical industry: Used in equipment such as reactors, storage tanks and pipelines to ensure safe operation under high temperature and high pressure conditions.

Power industry: Suitable for generator sets, boilers and other high-temperature equipment, effectively reducing leakage risks and improving energy utilization efficiency.

Metallurgical industry: Provide stable sealing performance and reduce production losses during smelting and heat treatment.

With the acceleration of global industrialization, the demand for high-performance sealing materials continues to grow. With its superior performance and broad application prospects, high-temperature nanographite Gland Packing are expected to usher in rapid development in the next few years. Industry experts said that with the continuous advancement of technology, the production process of nanographite Gland Packing will become more mature and the cost will be further reduced, which will pave the way for applications in more industries.

High-temperature Nanographite Gland Packing are an important innovation in the field of sealing materials, and their superior performance has enabled them to occupy a place in multiple industries.