Visoka temperatura fleksibilno samo -brtveni grafitni brtvi s korozijom

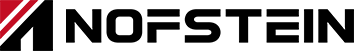

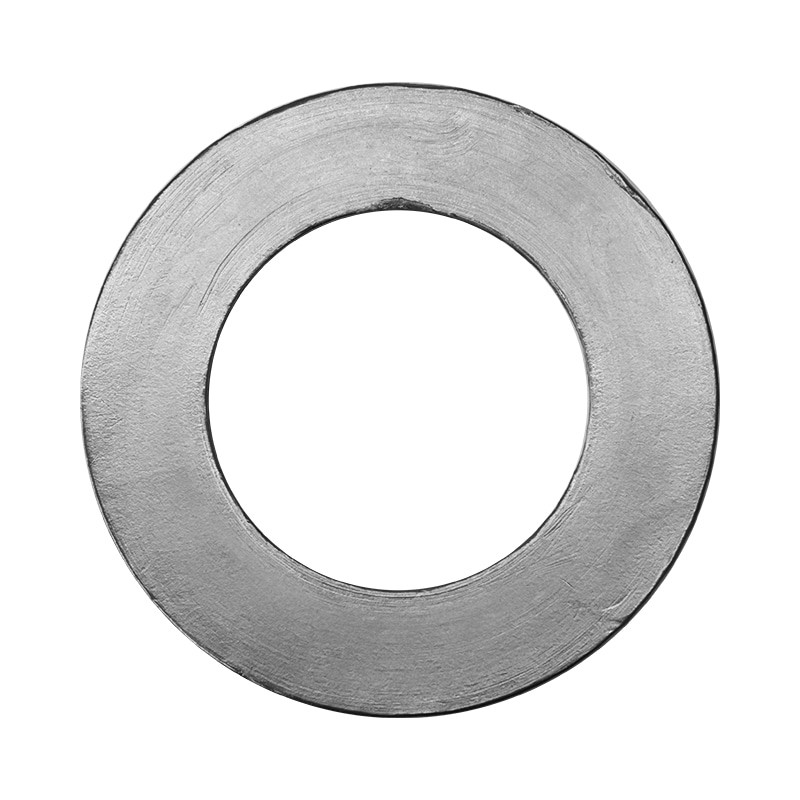

Prošireno pakiranje oblikovanog grafitnog brtve oblikovano je u prstenove prema zahtjevima veličine. Na elastičnost i strukturna svojstva pakiranja proširenog grafitnog brtve ne utječu na kemikalije. Može osigurati učinkovito brtvljenje bez gubitka zakretnog momenta. Također se može koristiti za brtvljenje vruće vode, visoke temperature i pare visokog pritiska. Tekućine prijenosa topline, vodikov plin, vodik, ista otapala, ugljikovodici, kriogene tekućine, itd .

Specifikacija

| Temperatura | -4 ℃- 3000 ℃ |

| Pritisak | 2MPA (rotacijska pumpa) |

| PH vrijednost | 0-14 |

| Brzina linije | 2m/s ~ 15m/s |

| Dostupne veličine presjeka | ≥1/8 ”~ ≤3” (3x3-75x75mm) |

| Gustoća | 1.30-1.60g/cm³ |

Predstavljanje proizvoda:

Visoka temperatura fleksibilno samozabjava grafitna brtva izrađen je od visokokvalitetnog proširenog grafita, s visokim temperaturnim otporom, može održavati stabilan učinak brtvljenja u ekstremnom temperaturnom okruženju, a najveći otpor temperature može doseći 850 ℃. Dizajn fleksibilne strukture može savršeno uklopiti različite složene prirubnice, realizirati funkciju samo-zalijepljenja i učinkovito sprječavati srednje istjecanje. Brtva je također otporna na koroziju, može se oduprijeti eroziji raznim kemijskim medijima i ima dug radni vijek. Naširoko se koristi u petrokemijskoj, električnoj energiji, brodogradnji i drugim industrijama.

Značajke proizvoda

Visoki temperaturni otpor: Radni temperaturni raspon je -4 ℃-3000 ℃, a neki vrhunski proizvodi mogu izdržati veće temperature.

Otpornost na koroziju: izvrsna otpornost na koroziju na većinu kemijskih medija (poput kiselina, alkalija i otapala).

Fleksibilnost i kompresibilnost: sposoban je prilagoditi se neravnim površinama i pružiti pouzdane efekte brtvljenja.

Snažna izdržljivost: dugi radni vijek i niski troškovi održavanja.

Visoka toplinska vodljivost: učinkovita disipacija topline za održavanje performansi sustava.

Kemijska kompatibilnost: pogodna za različite medije, uključujući naftna, plinska i kemijska otapala.

Ojačani dizajn: Neki su proizvodi ojačani od nehrđajućeg čelika ili metalne mreže kako bi poboljšali otpornost na tlake.

Područja primjene

Kemijska industrija: koristi se za brtvljenje opreme kao što su cjevovodi, ventili i reaktori kako bi se spriječilo curenje štetnih tvari.

Nafta i plin: pogodno za okruženje visokog tlaka i visokotemperaturne, kao što su cjevovodi, crpke i kompresori.

Power Industry: Pruža pouzdano brtvljenje u parnim sustavima visoke temperature u elektranama.

Proizvodnja automobila: koristi se u visokim temperaturama kao što su ispušni sustavi motora.

Farmaceutska i prehrambena industrija: U okruženjima koja zahtijevaju visoku čistoću grafitne brtve mogu spriječiti onečišćenje.

Papir i rudarstvo: Održavanje performansi brtvljenja u teškim radnim okruženjima.

ostati u kontaktu

-

U zahtjevnom krajoliku rukovanja industrijskim tekućinama, održavanje integriteta brtve u okruženjima s visokim temperaturama najveći je izazov za inženjere. Budući da centrifugalne pumpe i ventili...

naučiti više -

U visokotlačnim i visokotemperaturnim industrijskim okruženjima, postizanje hermetičkog brtvljenja najvažnije je za radnu sigurnost i usklađenost s okolišem. The valovita grafitna brtva ...

naučiti više -

U složenoj arhitekturi visokotlačnih cjevovoda, integritet prirubničkog spoja u osnovi ovisi o mehaničkim svojstvima metalni brtveni prsten . Za inženjere u petrokemijskoj, energetsko...

naučiti više

Samo-zalijepiti grafitne brtve: Nije li ovo nova revolucija u tehnologiji industrijskog brtvljenja?

U današnjem industrijskom polju inovacija tehnologije brtvljenja izravno je povezana sa stabilnošću, sigurnošću i zaštitom okoliša rada opreme. Jiangsu Jintai Blaing Technology Co., Ltd., sa svojim dubokim tehničkim pozadinama i neumoljivim inovativnim duhom, uspješno je razvio i promovirao rješenje za brtvljenje visokih performansi za brtveni brtvi samo-zalijepljenja, koje je donijelo revolucionarne promjene u mnogim industrijama kao što su isporuka, električna energija, čelik, kemijska industrija, strojevi itd.

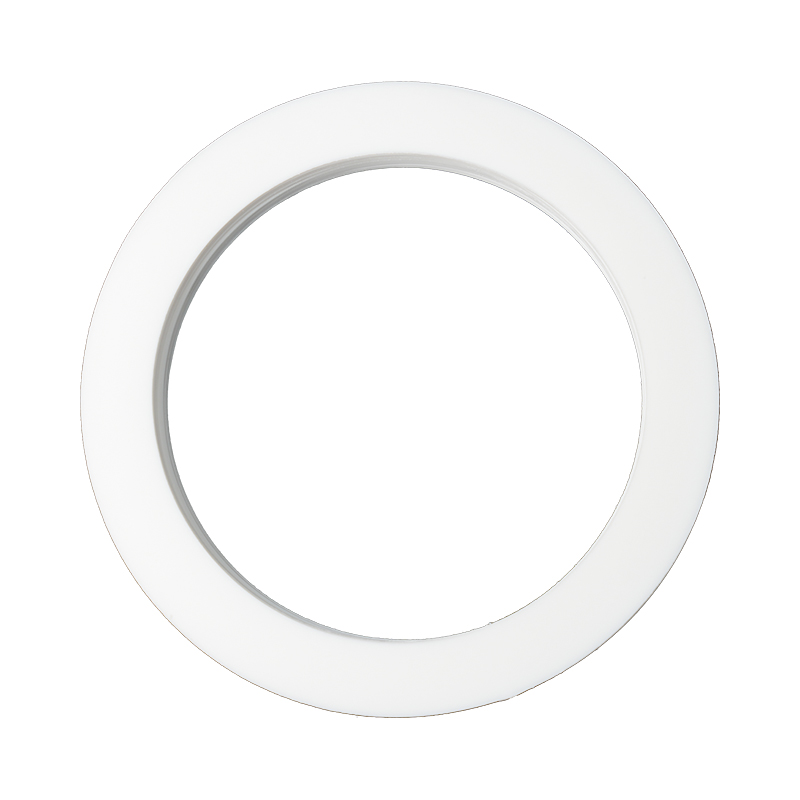

Kao zvjezdani produkt tehnologije za brtvljenje Jintai, samo-brtveni brtvi ističu se među mnogim materijalima za brtvljenje s izvrsnim performansama brtvljenja, izvrsnom otpornošću na visoku temperaturu i visoki tlak i dobru otpornost na koroziju. Brtva je izrađena od visokokvalitetnog grafitnog materijala i obrađuje se posebnim postupkom. Ne samo da zadržava izvorna izvrsna svojstva grafita, poput niskog koeficijenta trenja i visoke toplinske vodljivosti, već mu također daje jaču sposobnost samo-zalijepljenja i širu prilagodljivost.

Samo-zalijepci grafitne brtve mogu održavati stabilan učinak brtvljenja u različitim složenim radnim uvjetima, kao što su brze temperaturne promjene i fluktuacije tlaka. Njegov jedinstveni strukturni dizajn omogućava da se brtva automatski prilagodi i popunjava sitne praznine između za brtvljenje kada su podvrgnute vanjskim silama, tvoreći pouzdanu barijeru brtve, učinkovito sprječavajući srednje istjecanje i osiguravajući siguran rad opreme.

Sam grafitni materijal ima izuzetno visoku toplinsku stabilnost i kapacitet tlaka, što omogućava samo-zalijepljivim grafitnim brtvama da održavaju stabilne performanse brtvljenja u visokoj temperaturi i visokoj tlačnoj okolini. Bilo da se radi o parnom cjevovodu toplinske elektrane ili reaktoru petrokemijske industrije, samo-brtveni brtvi mogu se lako nositi s njom i pružiti pouzdanu zaštitu brtve za opremu.

Brz razvoj kemijske industrije iznio je veće zahtjeve otpornosti na koroziju za brtvljenje materijala. Svojom izvrsnom kemijskom stabilnošću, samo-brtveni brtvi mogu se oduprijeti eroziji različitih korozivnih medija kao što su kiseline, alkalije i soli, proširuju radni vijek opreme i smanjuju troškove održavanja.

Od svog osnivanja, Jiangsu Jintai Blailing Technology Co., Ltd., tehnološku inovaciju je uvijek smatrao temeljnom pokretačkom snagom razvoja poduzeća. Tvrtka ima tim za istraživanje i razvoj koji se sastoji od stručnjaka u industriji, viših inženjera i starijih tehničara, posvećen detaljnim istraživanjima i razvoju proizvoda za brtvljenje tehnologije. Kroz blisku suradnju s poznatim sveučilištima i znanstvenim istraživačkim institucijama u zemlji i inozemstvu, tehnologija zapečata Jintai kontinuirano se probijala kroz tehnička uska grla i promicala napredak industrije zapečatanja.

U procesu istraživanja i razvoja samo-zalijepljenih grafitnih brtvila, tehnologija brtvljenja Jintai usredotočena je na odabir materijala i optimizaciju procesa. Kroz ponovljene eksperimente i poboljšanja, niz samo-zalijepljenih grafitnih proizvoda za brtve s izvrsnim performansama i pouzdanom kvalitetom uspješno je razvijen kako bi zadovoljio potrebe za brtvljenjem različitih industrija i radnih uvjeta.

S izvrsnom performansama i pouzdanom kvalitetom, grafitne brtve za samo-zalijepiti tehnologiju Jintai-a, široko su se koristile u mnogim industrijama kao što su dostava, električna energija, čelik, kemijska industrija, strojevi itd. I postali su rješenje za brtvljenje koje vjeruje mnoge tvrtke. U budućnosti će se kontinuiranim razvojem industrijske tehnologije i sve većih zahtjeva za zaštitu okoliša, tehnologija brtvljenja Jintai i dalje pridržavati korporativne filozofije "inovacija, kvalitete i usluge", povećati ulaganja u istraživanje i razvoj, proširiti područja primjene proizvoda i pružati kupcima sveobuhvatniju i profesionalnu tehnologiju brtvila i usluge.

Jiangsu Jintai Blailing Technology Co., Ltd., samo-brtveni brtvi, postepeno postaju novo mjerilo u industriji brtve sa svojim izvrsnim performansama i širokim izgledima za primjenu. Radujemo se što će tehnologija brtvljenja Jintai i dalje voditi inovacijski trend tehnologije brtvljenja u budućem razvoju i više doprinosimo promicanju visokokvalitetnog razvoja industrije moje zemlje.